Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

Looking for a replacement product? Check out our LMI5500 Melt Flow Indexer

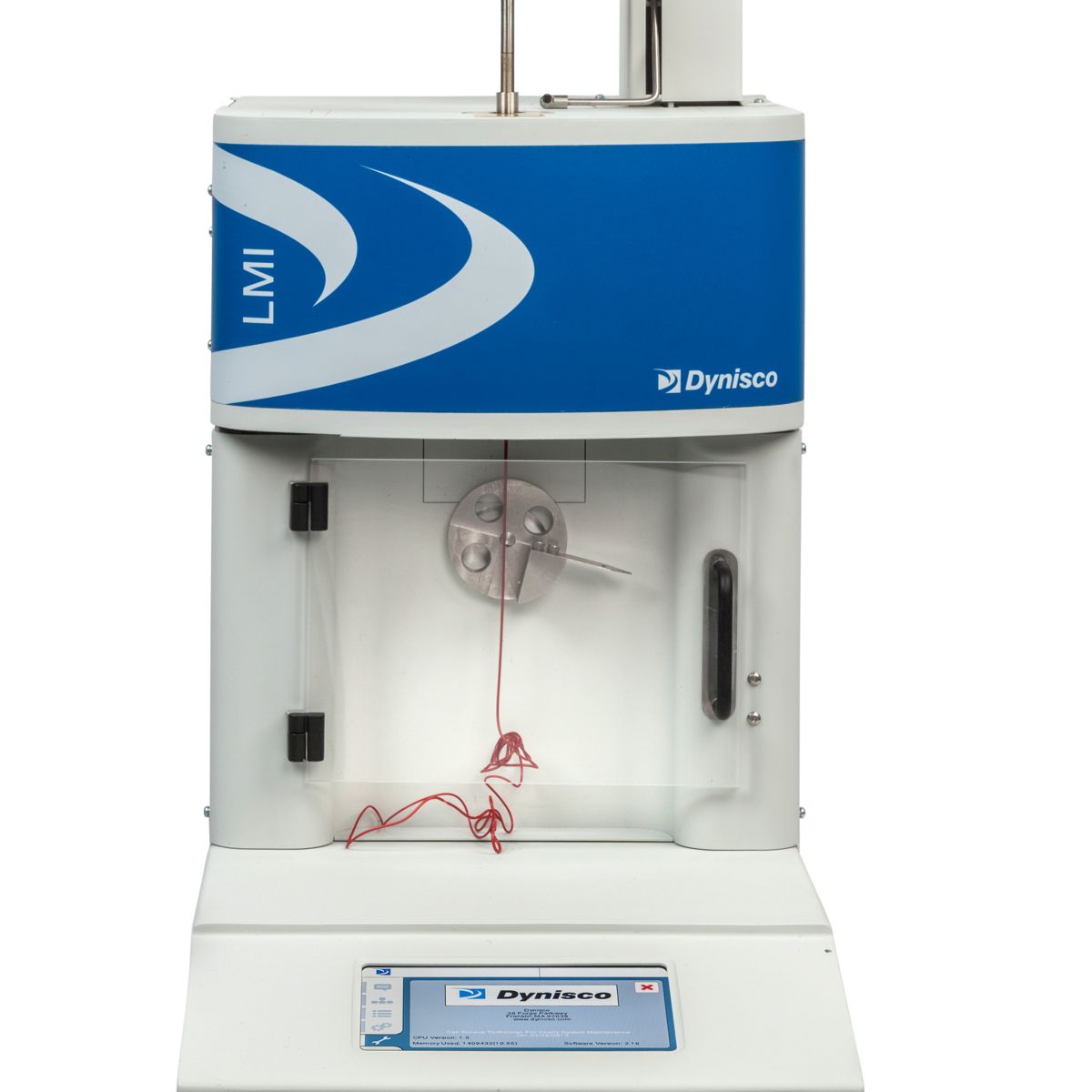

Setting the standard for accuracy and reliability when evaluating polymer melt flow characteristics. With the LMI5000 melt flow indexer, get quick and accurate measurement of melt flow characteristics to determine material quality, lot to lot consistency, and ensure what you are buying is in fact what you need.

Applications for Capillary Rheometers

From breakthrough technology in the industry’s most complete line of sensors to renowned quality and performance in indicators, controls, and analytical instruments Dynisco has demonstrated the skill, experience and know-how that not only deliver the right solution for your unique application, but also provide unparalleled customer support.

LMI Melt Flow Rate Test: Applications and Calculations

LMI5000 & LMI5500 SERIES COMPREHENSIVE OPERATOR TRAINING

To provide explanation and education of relevant ASTM test methods for obtaining Melt Flow Rate (MFR) Melt Volume Rate (MVR) and Melt Density (MD) of polymers, which will include comprehensive training on the set up, interface, operation, and general maintenance of the equipment.

LMI Melt Flow Indexer Accessory Reference Sheet

This reference sheet outlines the available accessories we offer for the maintenance and cleaning of your LMI melt flow indexer machine.

How Dynisco is Remolding the Plastics Industry Podcast

In this episode, Microsoft's podcast hosts Deb Oberly and Dani Diaz talk with John Biagioni, President of Dynisco, who is bringing our vision of "rheology to the masses" to fruition with trailblazing cloud solutions for the plastics industry. Learn about the details of our industry and company, the surprises and insights of our journey crafting their IoT solutions, the immense value of the data we are collecting and our deliberate approach for continued success in this space.

ASTM/ISO Method A/B Test Using the Dynisco LMI5500 Melt Flow Indexer

Dynisco melt flow indexers are used to evaluate the processability of materials. Get quick and accurate measurements of melt flow characteristics to determine material quality, lot to lot consistency, and ensure what you are buying is what you need. Let’s take a look at a specific use case for the LMI5500: the measurement of melt density through method A/B testing.

ASTM/ISO Method B Test Using the Dynisco LMI5500 Melt Flow Indexer

Get quick and accurate measurements of melt flow characteristics to determine material quality, lot to lot consistency, and ensure what you are buying is what you need. Let’s take a look at one of the specific ways you can speed the development, production, quality testing and analysis of your polymer- The ASTM/ISO Method B Test

Dynisco and Sustainability in the Plastics Industry

Sustainability is More than Protecting the Environment. Make Your Impact with Dynisco. Dynisco is dedicated to providing plastics processors and recyclers with accurate rheological information, helping to reduce waste and encourage sustainable practices

Dynisco IoT Cloud Connect: There For You 24/7 When You Can't Be

We are living in rapidly changing times. The entire world is working differently then we ever have in the history of manufacturing.Learn how the Dynisco IoT Cloud Connect and other support systems can help processors manage and monitor their production lines remotely

Dynisco Melt Flow Indexer Cleaning Procedures

Demonstrated here is the proper method of cleaning your Dynisco melt flow indexer after each test in order to maintain the machine's precision, accuracy, and longevity.

Dynisco Online Shop Overview

Dynisco’s Online Shop is where you can have access to ordering all Dynisco parts from Polymer Testing Equipment to Sensors to accessories- all to optimize your application.

Melt Flow Testing Article Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Melt Flow Testing Article Part 2

To fully appreciate the strengths and weaknesses of the melt-flow-rate (MFR) test it is important to know something about the way the test is performed.

Melt Flow Testing Article Part 3

There is a well-established relationship between something called the weight average molecular weight of a polymer and a parameter known as the zero-shear viscosity.

Melt Flow Testing Article Part 4

Few molders perform the test in-house. Of those that do, most don't understand why they are doing it or what they are measuring.

Melt Flow Testing Article Part 5

There are two points in the manufacturing supply chain where a determination of average molecular weight (MW) is important. The first is when the material is first received by the molder. The second is after molding.

Melt Flow Testing Article Part 6

Once degradation has been established, the discussion inevitably turns to how it happened. It might be expected that the answer to this question is widely known. Not so. The good news is that the influences that cause polymer degradation during processing are few.

Melt Flow Testing Article Part 7

Here is why the melt flow test is not universal. As useful as the melt flow rate (MFR) test can be, it is not universally applicable. Fundamentally, the test is intended to document differences in molecular weight.

Melt Flow Testing Article Part 8

Here are the steps to take in cases where the MFR is not provided by the polymer supplier. The number of commercial materials that employ a melt flow rate (MFR) value as part of the published property profile attests tO the usefulness of the test.

Melt Flow Testing Article Part 9

Understanding the value of melt-volume rate. If you spend a lot of time looking at data sheets you have probably noticed a trend over the last several years in how the melt flow rate (MFR) is reported. Along with, or instead of, the MFR, a new line item is appearing called the melt volume rate (MVR).

Dynisco has an extensive worldwide network of experts with thousands of years of combined pressure and application experience whose mission is to partner with you to optimize your system, solve problems and keep your operations efficient and cost-effective.

Simplified Rheology for the Masses

We address issues such as the need to test polymers, the correlation of lab values to online production, and the impact of melt flow index and viscosity on part quality and profitability.

Simplified Rheology: A Technical Discussion

Understand technical aspects of how parameters change between laboratory standards and production and how advanced equipment today can adjust for these differences.

Detecting Polymers in Material Products

It can be very difficult, if not impossible, to achieve complete indentification of most polymer products. However, in most cases, this is usually not needed; what is needed is the separation, or identification, of numerous molding materials whose identity has been lost, or an indication of the type of material used to create a component.

The LaVA Suite software for the new LMI5000 series has the look and feel of applications for the latest PCs or mobile devices. Screen layout and menu navigation is immediately intuitive to lab personnel of every skill level.

No longer are large, heavy weights needed to achieve all of the ASTM D1238 testing conditions. Operators will now be able to stack combinations of smaller, easier to handle weights to attain the desired overall weight. With the introduction of these new weights, we are also introducing a new, easier to understand part number system. Please use this document as a guide to the new part numbers as well as for suggestions on how to achieve the ASTM D1238 weight values.

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014