Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

Applications for Capillary Rheometers

From breakthrough technology in the industry’s most complete line of sensors to renowned quality and performance in indicators, controls, and analytical instruments Dynisco has demonstrated the skill, experience and know-how that not only deliver the right solution for your unique application, but also provide unparalleled customer support.

Introduction, Capillary Rheometers, LCR7000, Dynisco, Laboratory, Quality Control Testing, DyniscoEffects of Viscoelastic Properties of Polymer Melts on the Entrance Flow Pattern

Analyzing elastic properties and predicting flow instability of viscoelastic polymers is important for designing dies and flow systems in an extrusion process simulation or quality/process control purposes. This is even more essential for the processes that are involved with stretching of polymer melt such as film/sheet extrusion or blown film extrusion

LCR7000 Comprehensive Operator Training

To provide explanation and education of relevant ASTM test methods for obtaining apparent viscosity and shear rate measurements of polymers, which will include comprehensive training on the set up, LABKARS software interface, operation, and general maintenance of the equipment.

APT Technology Gateway - EMC and Dynisco

Dynisco and Sustainability in the Plastics Industry

Sustainability is More than Protecting the Environment. Make Your Impact with Dynisco. Dynisco is dedicated to providing plastics processors and recyclers with accurate rheological information, helping to reduce waste and encourage sustainable practices

Dynisco Online Shop Overview

Dynisco’s Online Shop is where you can have access to ordering all Dynisco parts from Polymer Testing Equipment to Sensors to accessories- all to optimize your application.

LCR7000 Series Capillary Rheometer

PET and polyolefin recycling Inline viscosity measurement

Check out a recent interview with Dynisco's Johannes Lorenz where he discusses inline viscosity measurement in PET and polyolefin recycling.

Dynisco has an extensive worldwide network of experts with thousands of years of combined pressure and application experience whose mission is to partner with you to optimize your system, solve problems and keep your operations efficient and cost-effective.

Simplified Rheology for the Masses

We address issues such as the need to test polymers, the correlation of lab values to online production, and the impact of melt flow index and viscosity on part quality and profitability.

Simplified Rheology: A Technical Discussion

Understand technical aspects of how parameters change between laboratory standards and production and how advanced equipment today can adjust for these differences.

The controlling factor in all polymer conversion processes is the materials rheological behavior. Check out this recent white paper in conjunction with EMC Electrical Mechanical Controls and Applied Polymer Technologies (APT) and learn how rheological measurements can detect the most discrete changes in structural properties.

Detecting Polymers in Material Products

It can be very difficult, if not impossible, to achieve complete indentification of most polymer products. However, in most cases, this is usually not needed; what is needed is the separation, or identification, of numerous molding materials whose identity has been lost, or an indication of the type of material used to create a component.

Key Violation in LabKars Software

The following instructions will resolve the key violation error that appears in Labkars software, which is used to control our LCR7000 series capillary rheometers

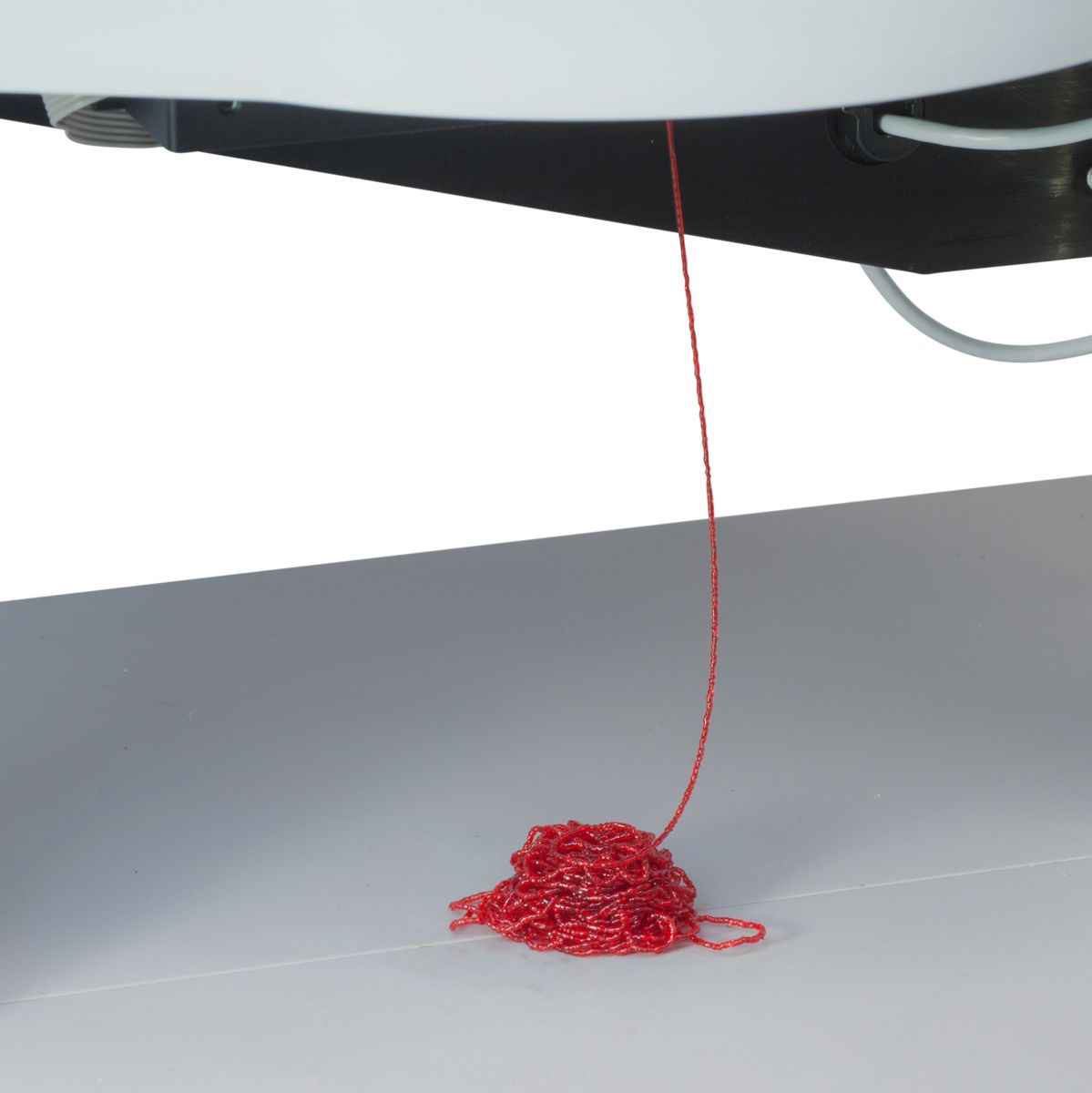

The Pressure transducer will allow the end user to monitor pressure in the capillary. High shear rate flow testing is commonly carried out by forcing the melted plastic material through a die of specified size, using piston at a known piston speed and material temperature. The pressure, or force, required to maintain the specified flow rate is measured. The piston speed is then changed and the new force or pressure generated at this speed, is measured and recorded. For each piston speed a force or pressure is recorded. Knowing the barrel dimensions and the piston speed, the volumetric flow rate through the die can be calculated. In turn the shear stress and the shear rate are calculated and used to construct flow curves.

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014